-

-

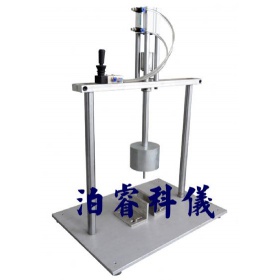

泊睿BR-PV-TBK接線盒孔口蓋擊開試驗機

- 品牌:泊睿

- 型號: BR-PV-TBK

- 產地:上海

- 供應商報價:¥20000

-

上海泊睿科學儀器有限公司

-

銷售范圍售全國

入駐年限第10年

營業執照

- 同類產品

立即掃碼咨詢

聯系方式:400-822-6768

聯系我們時請說明在儀器網(www.shangjinews.cn)上看到的!

掃 碼 分 享

詳細介紹

儀器簡介:

接線盒孔口蓋敲落試驗MST44

目的

組件接線盒壁上可敲落的孔口蓋在正常使用時的外力下應保持在原位,在現場安裝性配線系統時應能方便地敲落。

試驗條件

一個帶可敲落孔口的聚合物接線盒樣品將在環境溫度25C下“以收到樣品時的狀態”進行試驗;

另一個帶可敲落孔口的聚合物接線盒樣品將在-20±1C下放置5h。放置后該接線盒應立即重復上述試驗。

程序

試驗程序如下:

第一步 用一個最短38mm長、直徑6.4mm的平頭圓軸對敲落蓋施加44.5N的力,持續施力1min。施力方向與孔蓋平面垂直,加在最可能引起敲落蓋移動的位置。1h后測量孔蓋和接線盒壁的錯位。

第二步 用一個螺絲刀當鑿子,把敲落蓋擊開。敲落后允許螺絲刀刃邊沿已經打開的內壁劃一周,以除去留在邊緣上的碎片。

第三步 對另外兩個敲落蓋重復第一步和第二步。

如果接線盒的一個敲落蓋可以有多個直徑的開孔,當小直徑敲落蓋被擊開時,大直徑敲落蓋應無移動。

合格判據

敲落蓋在施加上述穩定的作用力后仍應保持在原位,并且所測敲落蓋和開口之間的錯位應不大于0.75mm。

敲落蓋應容易地敲落,且不造成任何尖銳邊緣或對接線盒產生任何損壞。

技術參數:1) 38mm長、直徑6.4mm的平頭圓軸

2) 接線盒夾具

3) 砝碼自動升降裝置...

主要特點:

參照IEC 61730:2-2004及EN 168相關標準設計

BR-PV-TBK Terminal Box Knockout Tester

Implementation of standards: IEC 61730-2:2004 & Ed.2, VDE 0126-5:2008, EN 168

Mandrel: minimum 38mm long by 6.4 mm diameter

Junction box fixture: adjustable

Load force: 44.5N

Mandrel and poise lifting: pneumatic control

The test for hydrostatic test, must reduce or eliminate the drop impact force influenceing test results.

Gas pressure method, adjustable speed, avoid the impact caused by direct terminal box knockout.

Mandrel and pressure bar is separate, when mandrel pressure to junction box, mandrel and pressure bar separate, At this time knockouts force only mandrel add poise, have nothing to do with gas pressure.

Attachment:

① Timer or mobile phone time

② Low temperature test chamber

③ Gap measurement and sharpness of edge determinationPurpose:

Removable hole covers in the walls of module terminal enclosures (knockouts) shall remain in place under nominal force application and also be easily removed for the field application of permanent wiring system components.

Condition:

A sample of the polymeric terminal box with knockouts will be tested in an “as-received” condition at a 25°C ambient temperature. Another sample of the polymeric box is to be conditioned for 5h in air maintained at -20°C±1°C. The test shall be repeated on the box immediately following this conditioning.

Procedure:

The knockout shall be easily removed without leaving any sharp edges or causing any damage to the box.

The procedure is as follows:

Step 1 A force of 44.5N shall be applied to a knockout for 1min by means of a mandrel, minimum 38mm long by 6.4 mm diameter, with a flat end. The force is to be applied in a direction perpendicular to the plane of the knockout and at the point most likely to cause movement. Wait 1 h and measure the displacement between the knockouts and the box.

Step 2 The knockout shall then be removed by means of a screwdriver, used as a chisel. The edge of a screwdriver blade may be run along the inside edge of the resulting opening once only, to remove any fragile tabs remaining along the edge.

Step 3 Repeat steps 1 and 2 on two additional knockouts. For a box employing multi-stage knockouts, there shall be no displacement of a larger stage when a smaller stage is removed.

Pass criteria:

The knockout shall remain in place after the application of the steady force and the clearance between the knockout and the opening shall not be more than 0.75 mm when measured. The knockout shall be easily removed without leaving any sharp edges or causing any damage to the box.